Veröffentlicht :31.08.2020 07:12:57

Klicken Sie auf Zählen:2103

Yovav Sameah, President of Frontline PCB Solutions, said: "InShop can help PCB manufacturers analyze and utilize the large amounts of data generated by machines throughout the workshop and turn them into executable solutions." We are committed to providing manufacturers with the collected data The intuitive view of the system accelerates the detection of faults and anomalies, thereby minimizing the impact on productivity and efficiency. "

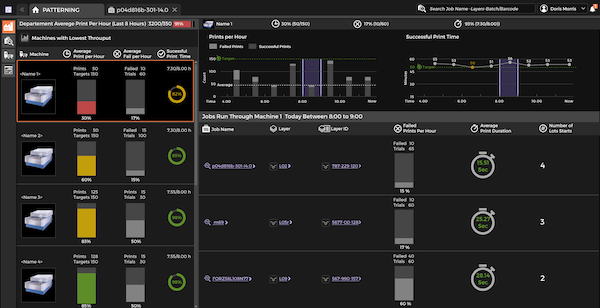

In the manufacturing process, a large amount of machine data is generated every day. To maximize the manufacturer’s production quality and efficiency, it is necessary to collect, measure and analyze these data, and immediately take targeted measures. There is no doubt. With the increasingly fierce competition in the manufacturing of high-end electronic products, PCB manufacturers are also seeking to increase their differentiated positioning, and the use of these data has become indispensable. InShop's advanced analysis and industrial 4.0 functions can empower PCB manufacturers to collect and analyze massive amounts of data, and make near-real-time intelligent decisions based on executable result data.

InShop's advantage in PCB data analysis is based on Frontlines' 25 years of experience and expertise in PCB manufacturing, deep understanding of the industry, and its leadership in the CAM and engineering software solutions market.

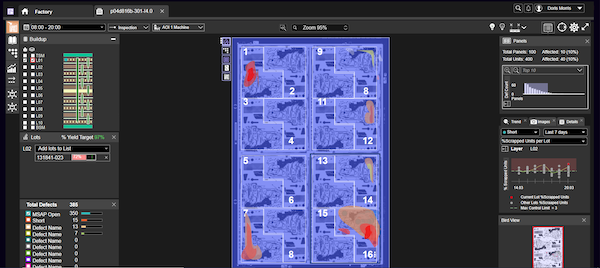

By using data collected from various machines in the workshop (including process parameters, machine utilization, and scrap data), InShop can quickly find anomalies and trends, enabling manufacturers to perform root cause analysis and provide actionable insights to improve manufacturing Quality and efficiency.

InShop, as Frontline's industrial 4.0 solution, is part of Frontline's global leading integrated software solution series. It can automate the entire pre-production process of PCB manufacturing, including quotation preparation to process planning and CAM processing, and then throughout the entire Production workshop.